Rodmills

Rodmills Details

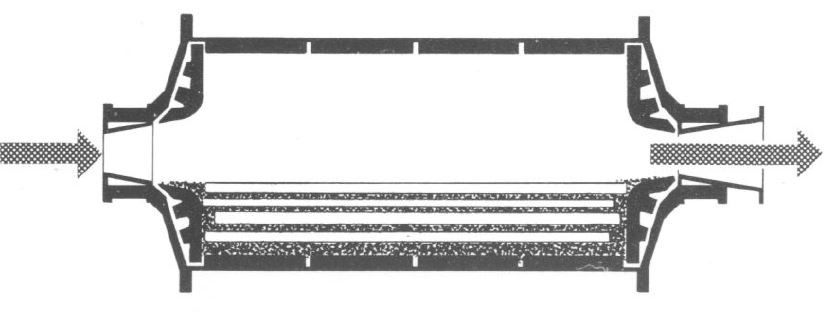

OFcon - Officine Contessacciai srl builds customized rodmills of any diameter, length and weight (possible replacement of old machines on existing concrete foundations) for grinding and reduction to sand of very hard materials such as rocks, glass, crystals and recycling and volume reduction of materials such as rockwool and glasswool using tree types of drums depending on the types of productions:

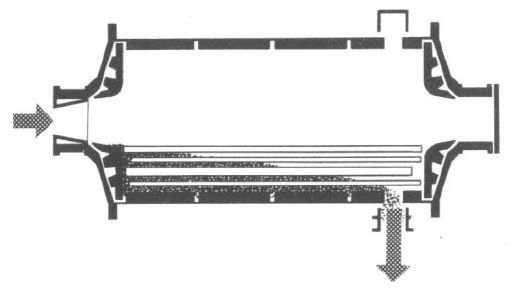

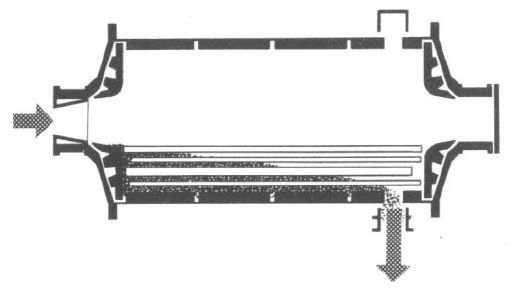

with lateral discharge LD

with central discharge CD

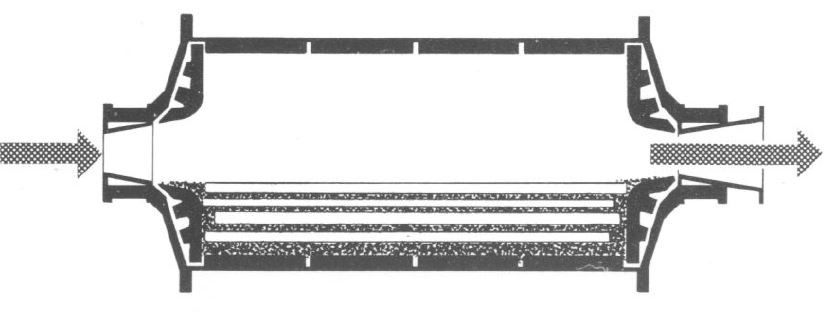

with axial discharge AD

and two types of transmission:

- PCT: electrical motor, elastic joint (or hydraulic coupling), gearbox, toothed coupling, countershaft with pinion and big toothed crown fixed on the drum.

- DT: electrical motor, elastic joint (or hydraulic coupling), big gearbox, big toothed coupling and big shaft in the transmission head

Standard production is with the following diameters and details:

| Rodmill type | Internal diameter (mm) | Drum length (mm) | Discharge type | Type trasmission | Power (KW) |

|---|---|---|---|---|---|

| RM12 | 1200 | 2400/3000 | LD,CD,AD | PCT,DT | 45/55 |

| RM15 | 1500 | 3500 | LD,CD,AD | PCT,DT | 75/115 |

| RM18 | 1800 | 3500/3600 | LD,CD,AD | PCT,DT,GMD | 90/132 |

| RM21 | 2150 | From 4500 | LD,CD,AD | PCT,GMD | 160/250 |

| RM24 | 2400 | From 4800 | LD,CD,AD | PCT,GMD | 250/355 |

Coding example: RM 1836 LD/DT

- RM 18 (1800mm of drum) 36 (3600mm drum length) LD (lateral discharge) DT (direct transmission)

(with discharge CD and AD not possible DT transmission

Optional available:

- internal lining of drum in rubber/metal or manganese steel casting plates

News 2023 the manganese steel lining of drum with new drawing, high wave and manganese 18% - mechanic safety drum block during maintenance (*)

- feeder screw or conveying trough (*)

- discharge conveyor belt (*)

- total safety fence (*)

- electrical cabinet with frequency control (*)

- man pass on the drum (only in the BM12/15/18)

- lubrication system (*)

- high quality forged balls charger

(*) Mandatory for GMD rodmill

NEWS 2024

GMD RODMILL (GEARLESS MOTOR DRIVE)

THE FIRST RODMILL WITH THIS TECNOLOGY IN THE WORLD

This project meets the requirements of:

- Industry 4.0 (total control of production)

- energy saving (from 25% to 35% less energy consumption)

- green economy (absence of worn oils and greases of motor, joints, gearbox, etc..)

- zero maintenance (only replacement of wear parts inside the drum)