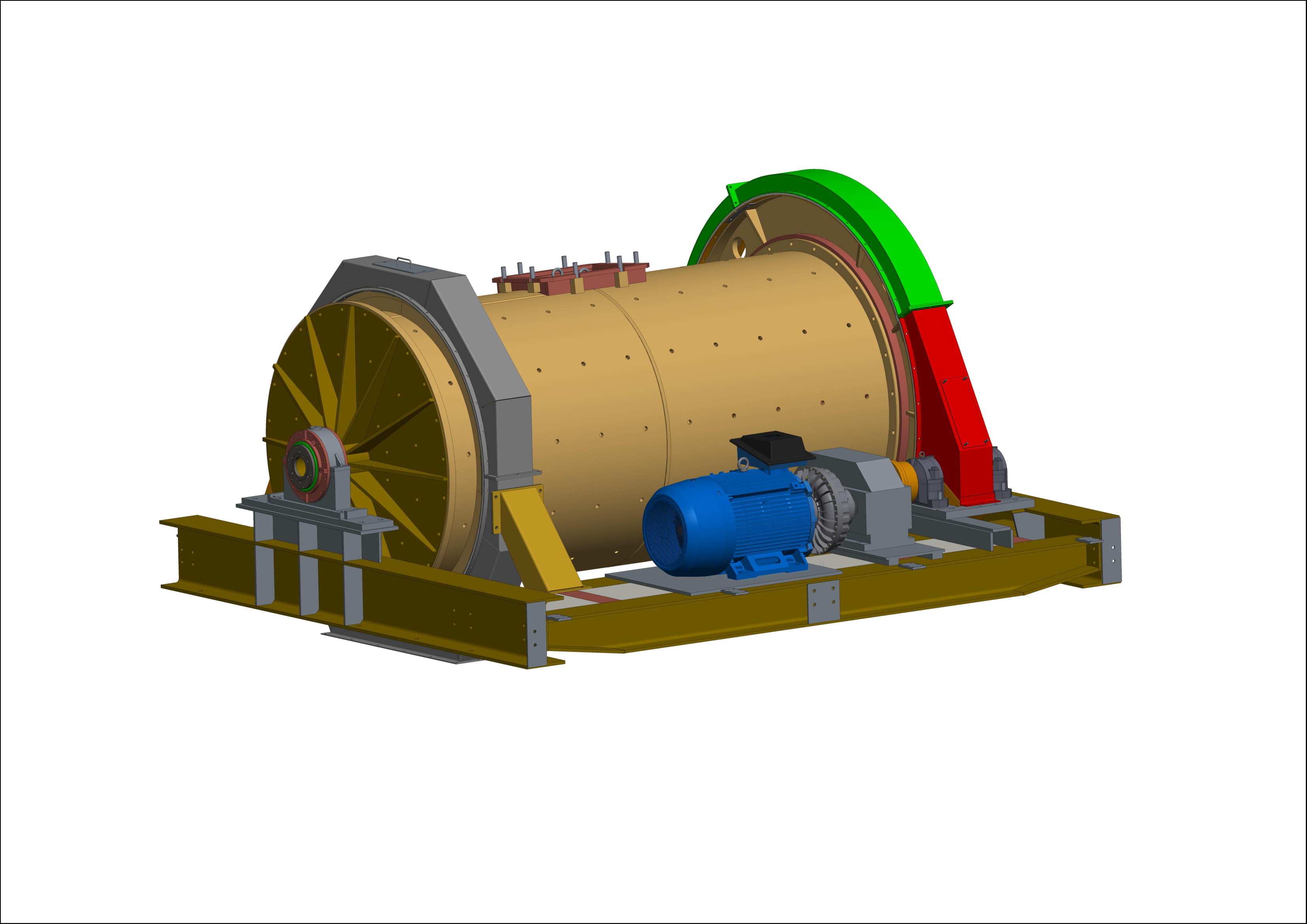

Spare parts for ball and Rodmills

Grinding bars

Our grinding bars are produced with selected, high quality raw materials rigorously from Italian steel mills with our chemical analysis studied and tested over the years, guaranteeing excellent crushing and avoiding breakages or anomalous wear of the bars.

With the use of our bars, having constant hardness and chemical analysis, the customer is able to calculate the wear times and therefore plan the reordering of the material over time.

We always have material ready in stock and are available for annual or biennial supply contracts.

Technical characteristics of grinding bars for our quality Rodmills

Range of chemical analisys on product

| C | Mn | Si | S | P | Cr |

|---|---|---|---|---|---|

| 0.50 0.60 |

0.80 1.40 |

0.45 MAX |

0.035 MAX |

0.035 MAX |

0.60 1.20 |

Mechanical properties

| Tensile strenght N/mm2 | Yeld Point N/mm2 | Elongation % | Hardness HB |

|---|---|---|---|

| 740 1000 |

450 600 |

15 MAX |

240 280 |

- It is certified that the product relating to this document complies with the requirements cited in the use and maintenance manual of our RM12, RM15, RM18, RM21, RM24 type Rodmills

- The products are 100% checked to guarantee correct wear and absolutely avoid breakages of the bars

- For a correct evaluation of the type of chemical analysis to be used for the bars, we recommend contacting us and telling us what type of aggregate the bar mill will be fed with.

- The material complies with Dir. N. 2000/53/EC Heavy metals ED EN 10204/05 - 3.1

Comparative table theoretical weights of grinding bars for RM12, RM15, RM18, RM21, RM24 machines

(These weights are not binding and the material is weighed before shipping)

Other lengths are available on request

| Bar Length in MM | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2920 | 3050 | 3200 | 3300 | 3355 | 3420 | 3700 | 3800 | 4150 | 4850 | |

| Ø in mm | Theoretical weight of bars in kg | |||||||||

| 50 | 45 | 47 | 49.4 | 50.9 | 51.8 | 52.8 | 57 | 58.6 | 64 | 74.8 |

| 55 | 54.4 | 56.9 | 59.7 | 61.7 | 62.6 | 63.8 | 69.2 | 70.9 | 77.6 | 90.7 |

| 60 | 64.8 | 67.8 | 71.1 | 73.26 | 74.5 | 76 | 82.2 | 84.4 | 92.1 | 107.7 |

| 65 | 76 | 79.5 | 83.4 | 85.8 | 87.4 | 89.1 | 96.2 | 99 | 107.9 | 126.1 |

| 70 | 88.2 | 92.2 | 96.7 | 99.6 | 101.4 | 103.4 | 111.7 | 114.8 | 125.3 | 146.6 |

| 75 | 101.3 | 105.8 | 111 | 114.5 | 116.4 | 118.7 | 128.4 | 131.8 | 144 | 168.3 |

| 80 | 115.3 | 120.4 | 123.6 | 130.5 | 132.4 | 135 | 146 | 150 | 163.9 | 191.9 |

| 85 | 129.8 | 135.6 | 142.3 | 146.8 | 149.2 | 152.1 | 164.6 | 169 | 184.7 | 215.8 |

| 90 | 144.4 | 150.9 | 158.3 | 164.7 | 166 | 169.2 | 185 | 188 | 207 | 242 |

| 95 | 162.3 | 169.8 | 178.1 | 183.5 | 186.7 | 190.3 | 205.7 | 211.5 | 230.7 | 269.6 |

| 100 | 180 | 188.1 | 197.3 | 205 | 206.9 | 210.9 | 228 | 234.3 | 255.9 | 299.5 |

| 105 | 198.5 | 207.4 | 217.6 | 224.4 | 228.1 | 232.5 | 251.6 | 258.3 | 282.2 | 329.8 |

| 110 | 217.9 | 227.6 | 238.8 | 246.1 | 250.3 | 255.2 | 276 | 283.5 | 309.6 | 361.8 |

| 115 | 238 | 248.7 | 261 | 269 | 273.6 | 278.9 | 301.6 | 309.9 | 338.2 | 395.3 |

| 120 | 259.3 | 270.8 | 284.1 | 293 | 297.9 | 303.7 | 328.5 | 337.4 | 368.5 | 430.7 |

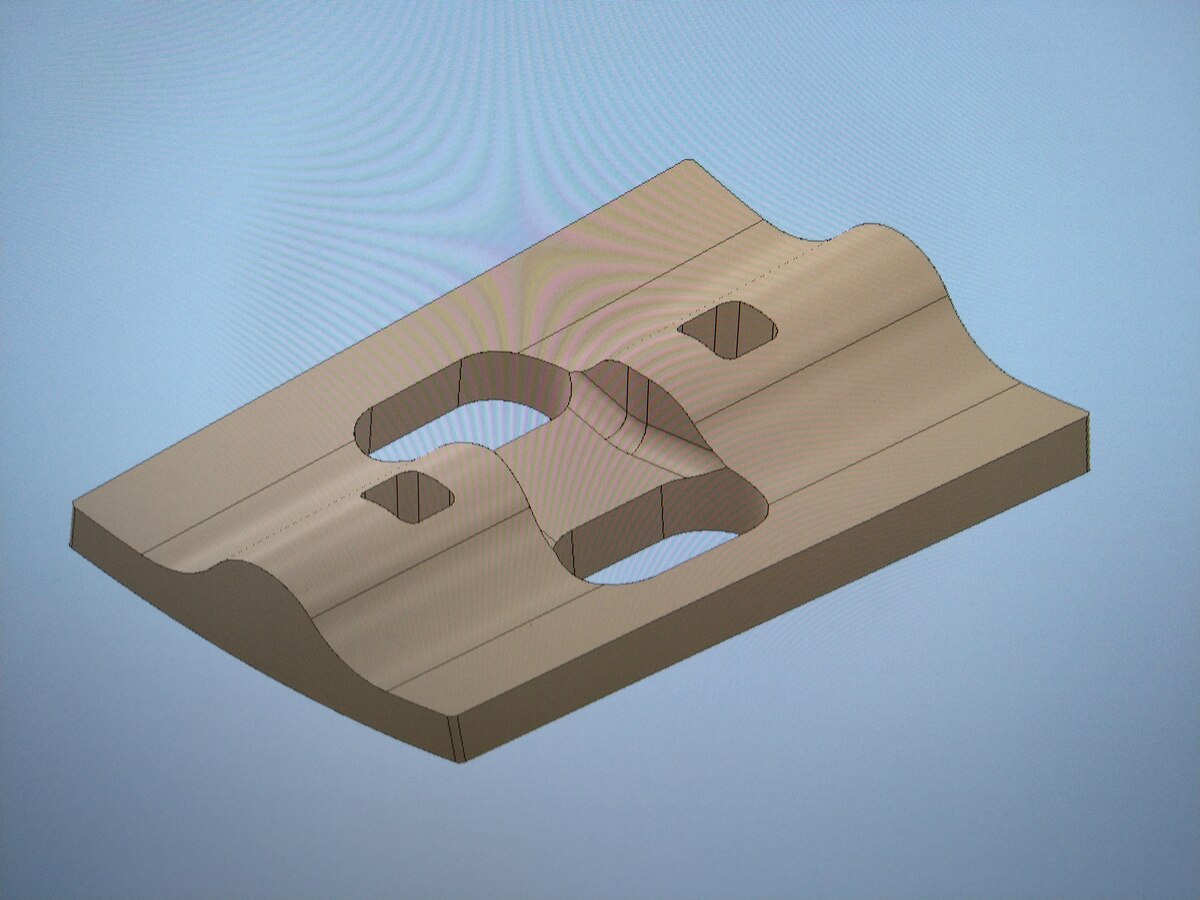

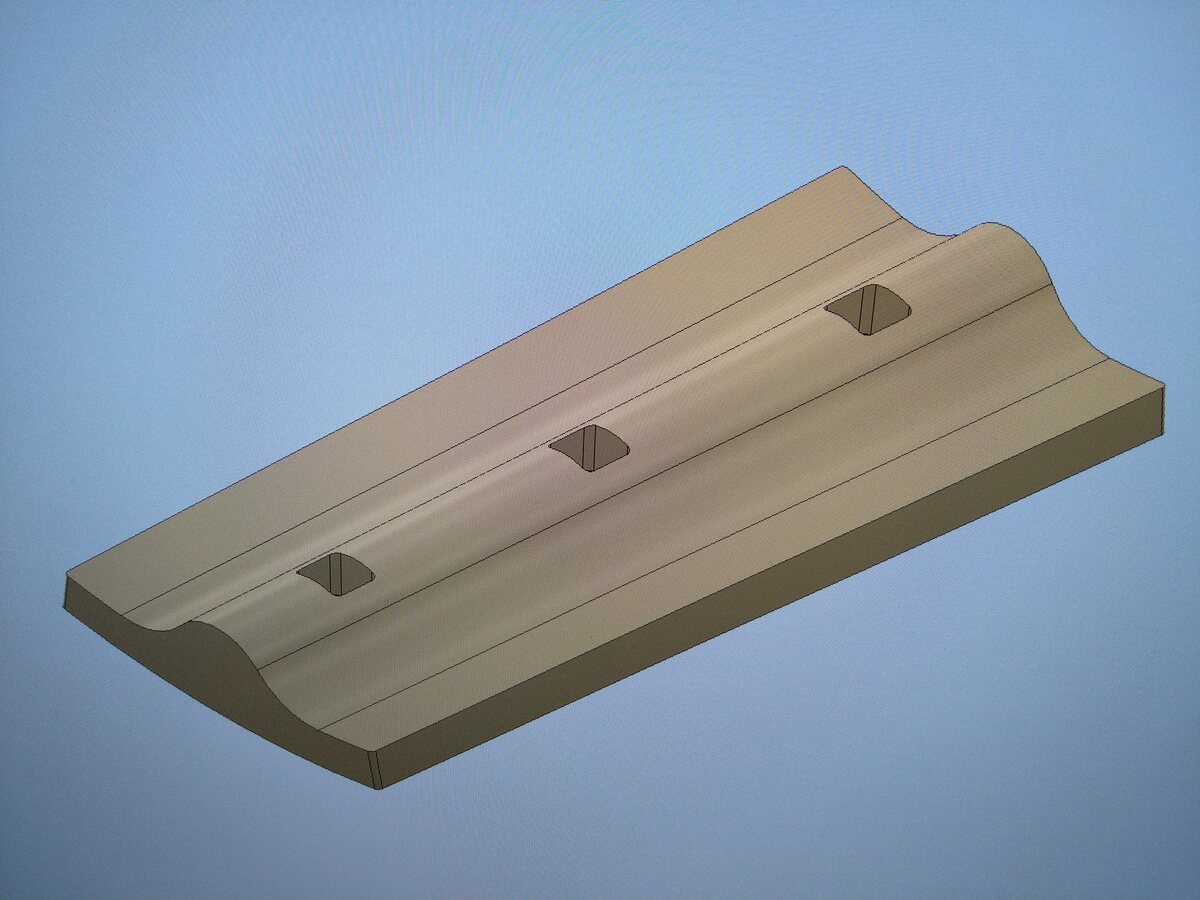

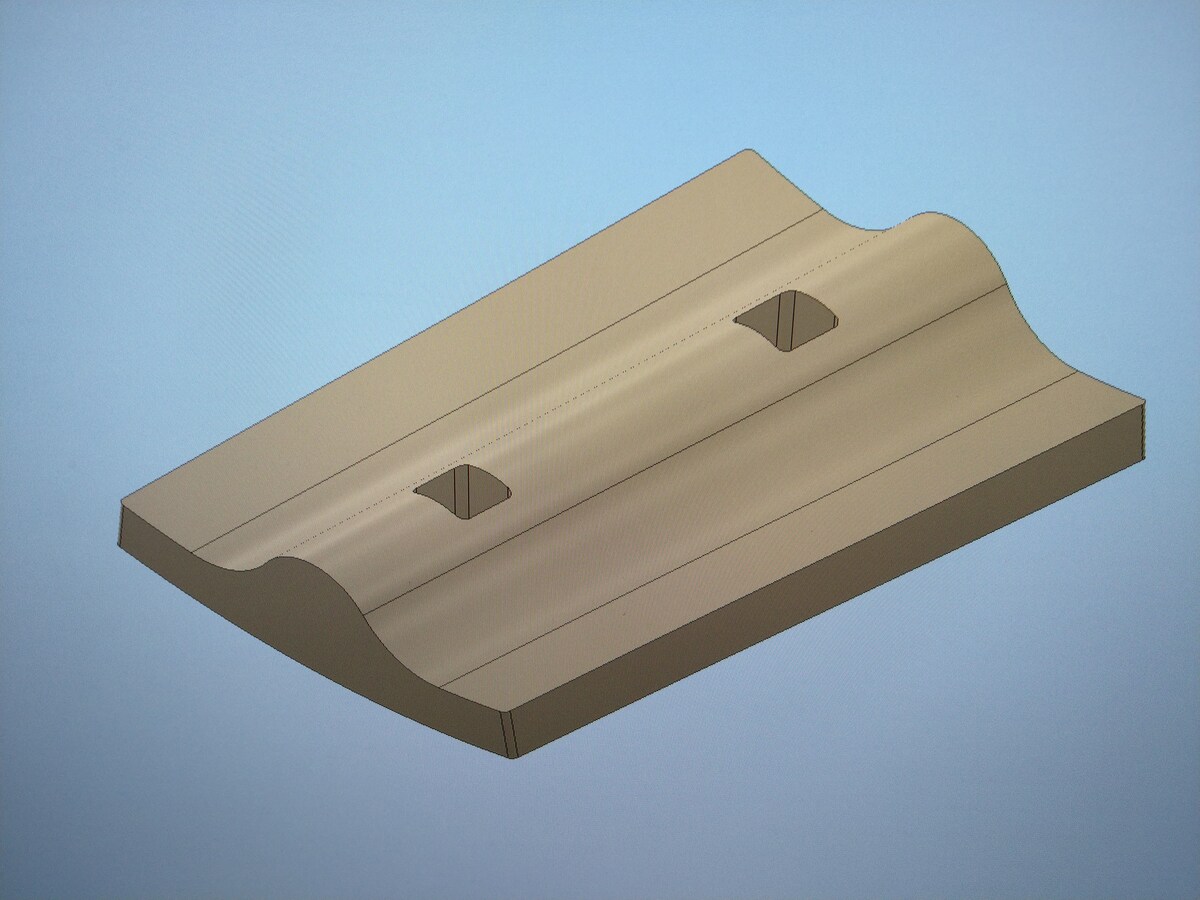

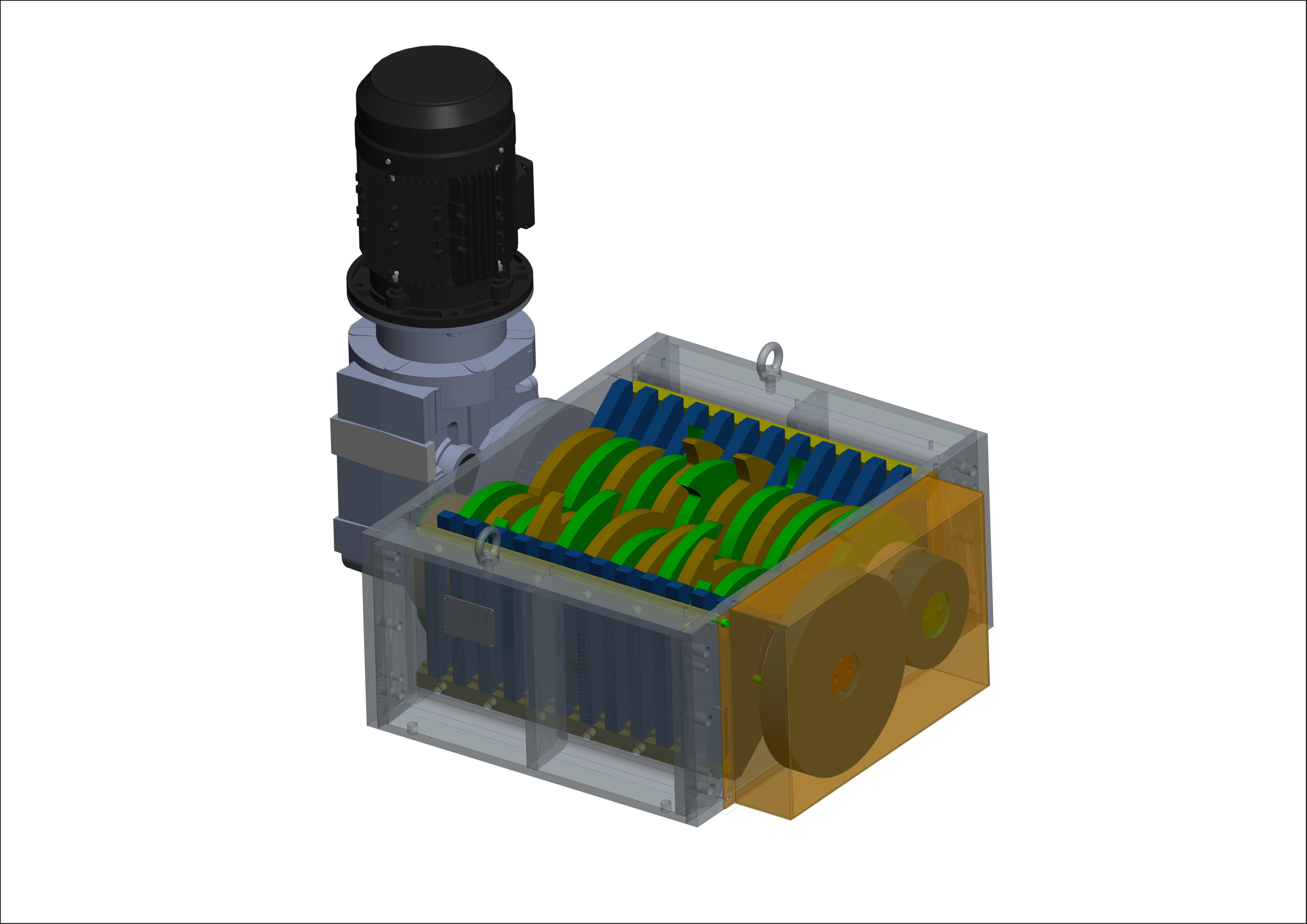

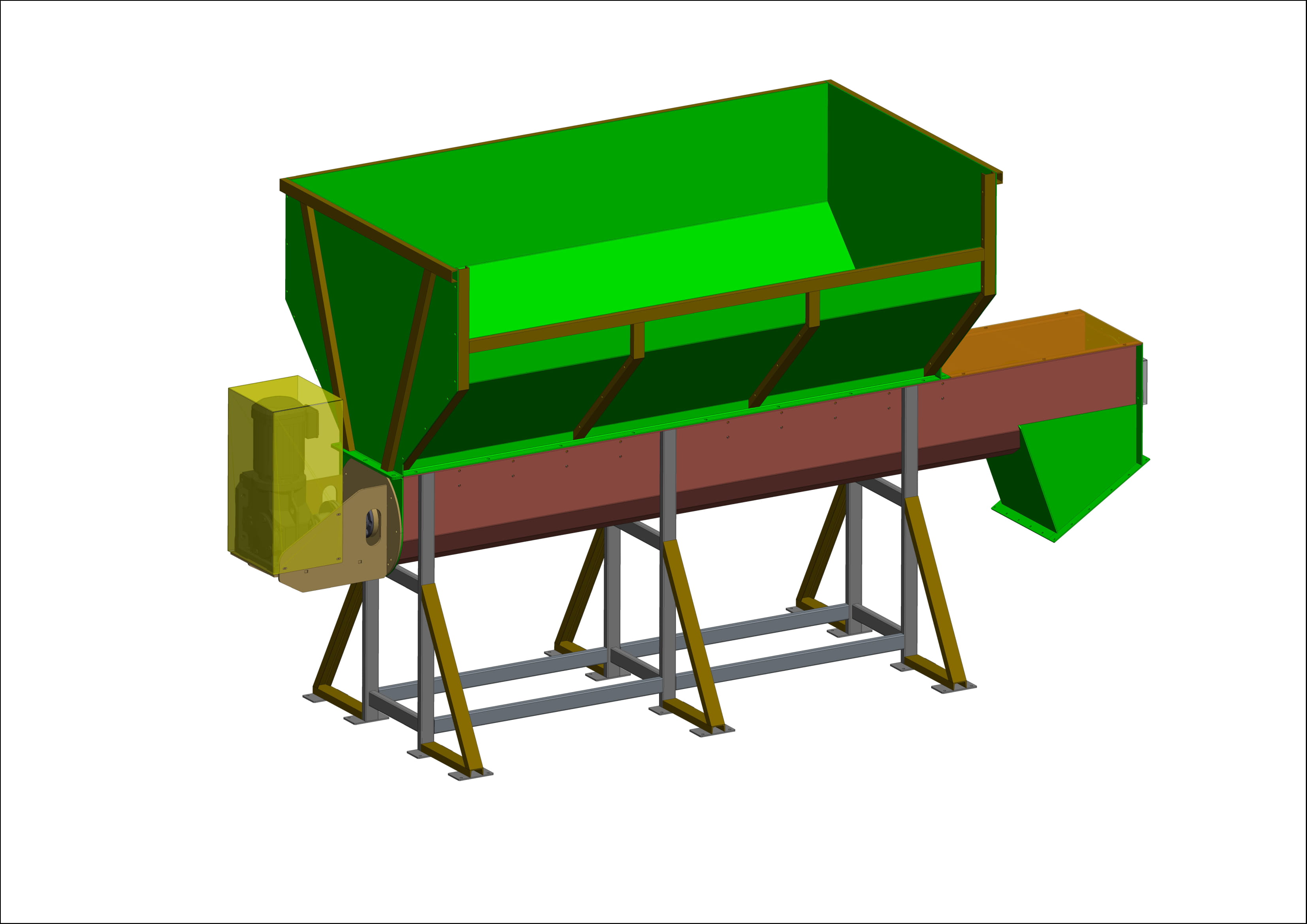

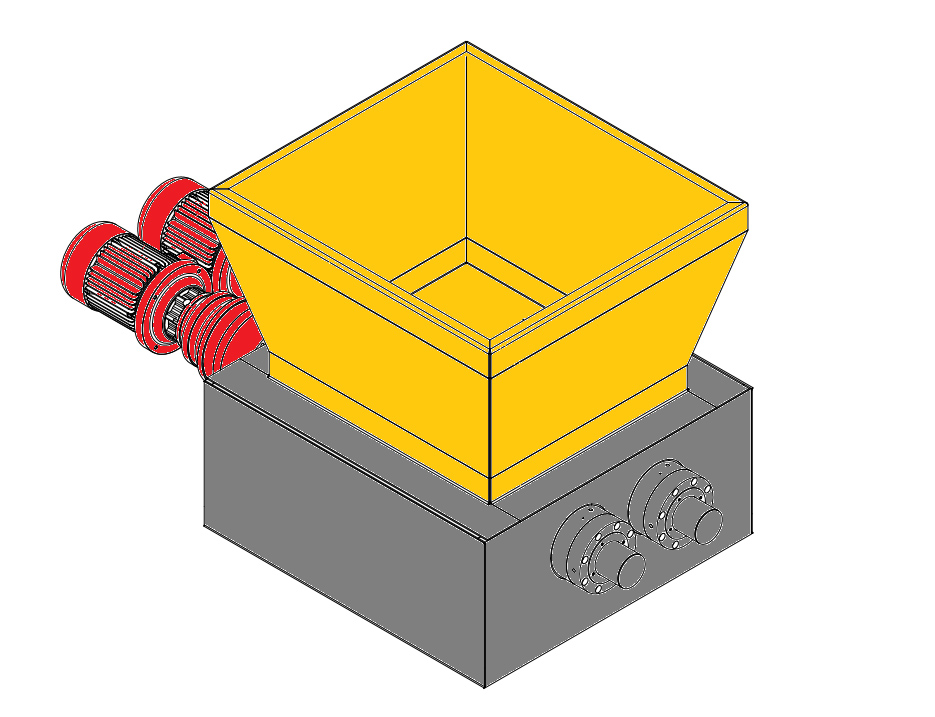

Custom manganese castings

Our technical office is able to design customized coatings and, thanks to our international partners, produce coatings in anti-wear manganese castings, in chrome alloy or in ceramic material for the treatment of any material and avoiding contamination due to wear of the parts grinding.

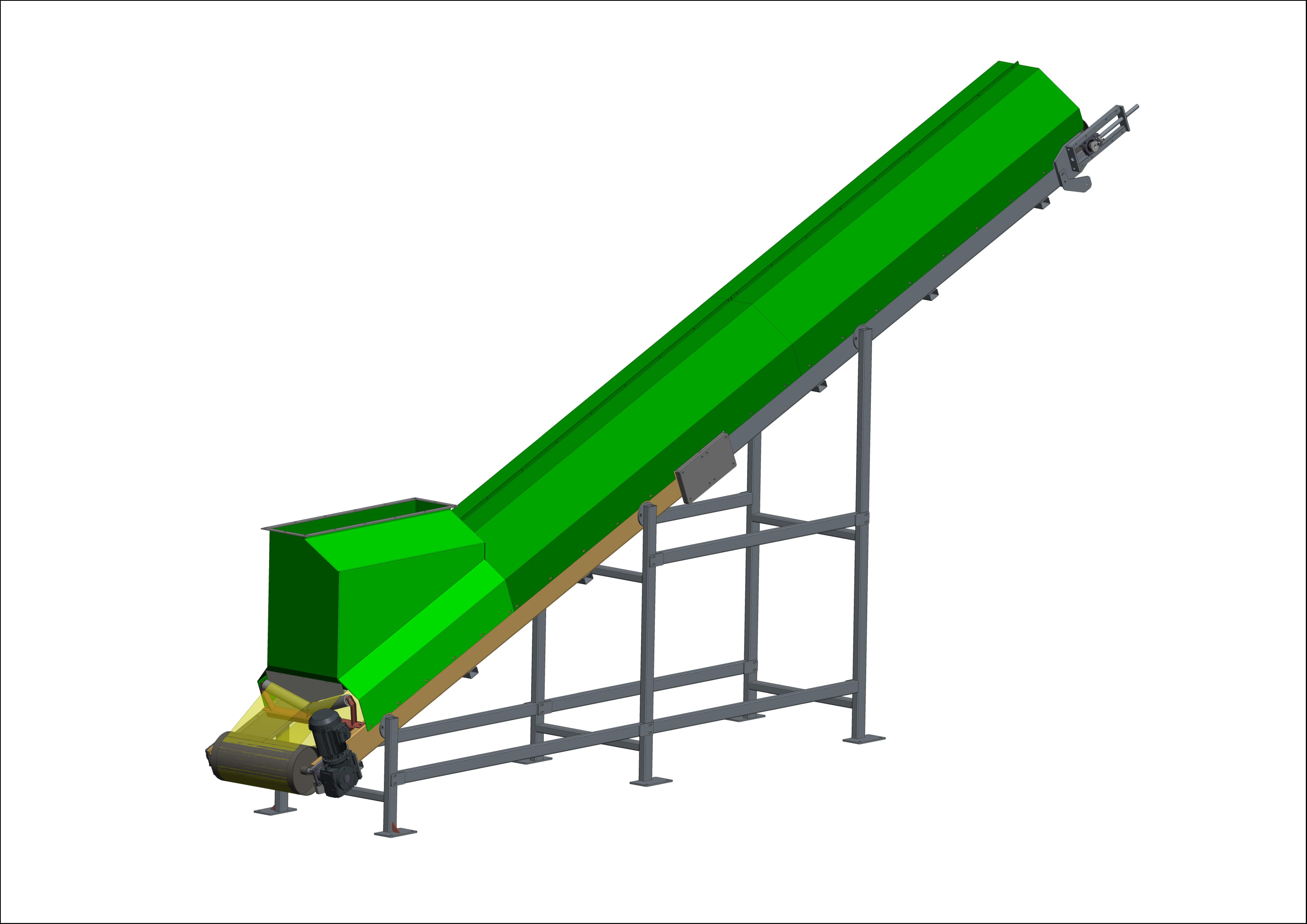

Rubber linings

Our technical office is able to design customized anti-wear rubber coatings for any bar, ball or SAG mill and thanks to our partners guaranteeing short delivery times.

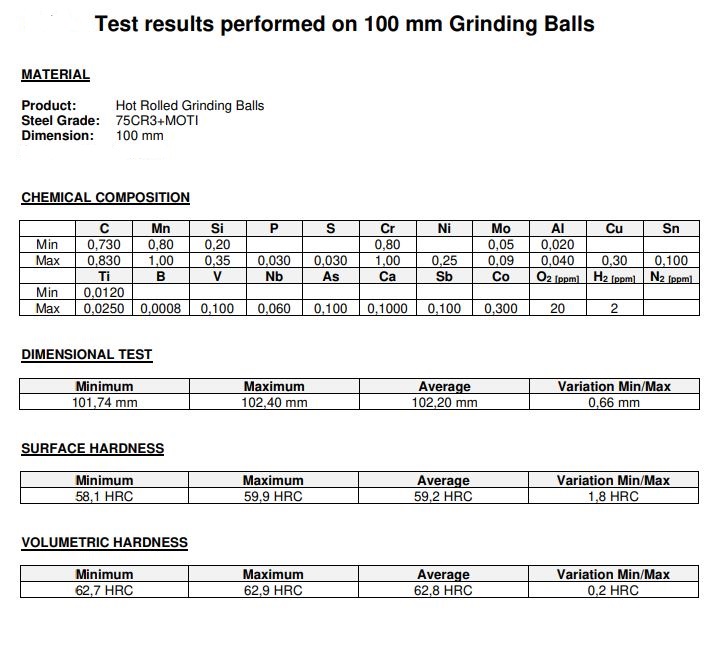

Steel grinding balls

We have the possibility to ship both in big-bags (1 or 2 Ton) or metal drums on pallets.

Technical specifications and quality range

| NOMINAL BALL DIAMETER [mm] | NOMINAL BALL WEIGHT [kg] | NUMBER OF BALLS PER TONNE [no.] |

|---|---|---|

| 30 | 0.111 | 9,011 |

| 40 | 0.263 | 3,801 |

| 50 | 0.514 | 1,946 |

| 60 | 0.888 | 1,126 |

| 70 | 1.410 | 709 |

| 80 | 2.104 | 475 |

| 90 | 2.996 | 334 |

| 100 | 4.110 | 243 |

| 110 | 5.471 | 183 |

| 125 | 8.028 | 125 |

| 130 | 9.030 | 111 |

| 140 | 11.279 | 89 |

| 150 | 13.872 | 72 |

| QUALITY | HARDNESS ROCKWELL C [HRC] | MAIN FEATURE |

|---|---|---|

| Full Hardness | 60-65 | high abrasion resistance |

| Intermediate Hardness | 55-60 | combining impact and abrasion resistance |

| Reduced Hardness | 48-55 | high impact resistance |

PRODUCT TYPE

| BALL DIAMETER [mm] | APPLICATION |

|---|---|

| 30-50 | regrinding ball |

| 60-90 | mill ball |

| 100-150 | sag ball |

Special bolts

We supply special bolts as replacement for many types of mills (even old mills out of production). Contact us for the production of special bolts by drawings.